Designed to Control Emulsions and Neat Oil Mist in Various Applications

In all metal fabrication with oil mist troubles, these filters will fit into a ducting system, connected to each machine. All units are equipped with a pressure gauge for control of filters as well as an indication for need of cleaning (self draining).

Suitable for emulsion mist and neat oil. (24-hour fine particle standard 35μg/m³ and annual fine particle standard 15 μg/m³)

Product Features

|

- Low maintenance cost

- Self draining filter

- Simple installation

- High filtration efficiency

- Designed to take up very little space

|

Applications

|

- Lathing and milling

- Machine stamping and pressing steel plates

- Industrial washing machines

- Abrasive water jets

|

Dimensions

|

- Height: 52" - 59"

- Width: 36"

- Depth: 32"

See the dimension images above for details in mm. |

Product Specifications

| Filter.Material |

Polyester |

Info & Guides

Operation

|

|

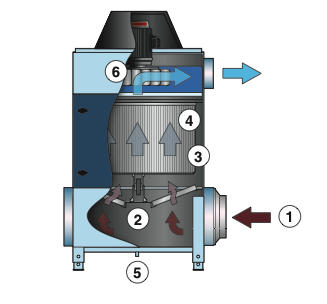

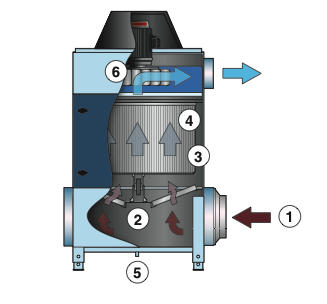

1. The contaminated air from the process is drawn into the lower chamber. 1. The contaminated air from the process is drawn into the lower chamber.

2. The coarse pre-filter separates large oil drops and particles. The coarse pre-filter is washable.

3. The main filter separates most of the oil mist and has a self draining function, and therefore becomes saturated with oil/emulsion which means that the filter can handle large amounts of oil/emulsion. The main filter is washable. Filtration efficiency >97.5% for oil mist.

4. All NOM filters can be equipped with HEPA filter which meets the demands from authorities on effective filtration. The HEPA filter is not washable. Filtration efficiency >99.97% for oil mist.

5. Return drainage pipe. The oil is drained back to a collecting tank or to the machine.

6. Integrated fan

|

For pricing, ordering or more information about the NOM 11 Oil Mist Collector, contact us.

1. The contaminated air from the process is drawn into the lower chamber.

1. The contaminated air from the process is drawn into the lower chamber.